Choosing the Right CNC Machine Shop

August 2, 2024

The Critical Role of CNC Machining in Medical Device Manufacturing

October 1, 2024Our world is increasingly shaped by complex technologies that evolve rapidly, often leaving us to wonder about the intricate parts, like gears and components inside machinery, that keep everything running smoothly. The answer to how these parts are made often lies in CNC precision machining.

CNC (Computer Numerical Control) precision machining has become the cornerstone of modern manufacturing, enabling the production of parts at extraordinary speeds and with unparalleled accuracy. This technology has revolutionized industries by simplifying manufacturing processes and delivering consistent, high-quality results.

Let’s dive into what precision machining is, the steps involved, the tools required, and why it’s so essential.

For all your precision Machining needs contact Atscott MFG. Located in Pine City, MN

What is Precision Machining?

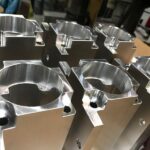

Precision machining is a specialized form of CNC machining that uses computer-controlled tools to produce parts with extremely tight tolerances and complex geometries. This high-speed process is capable of creating intricate components that fit and function together seamlessly.

Precision machining is a subtractive manufacturing process, meaning it starts with a solid block of material and removes excess material to create the final product. This method is widely used in industries that require parts with precise dimensions and smooth finishes.

The Key to Successful Precision Machining

Successful precision machining depends on two crucial elements:

- High-Quality Cutting Tools: Precision machining requires cutting tools that can meticulously remove material to achieve the exact dimensions needed for the part.

- Advanced CNC Machines: These machines, often incorporating high-speed robotics, control the cutting tools with extreme precision. The CNC machine directs the cutting tool or workpiece based on a programmed set of instructions.

Steps in the Precision Machining Process

Precision machining typically follows a series of structured steps to produce high-quality parts:

1. Design the Graphical Model

The process begins with creating a detailed graphical model of the part using Computer-Aided Design (CAD) software. Designers use CAD to develop 2D and 3D models that accurately represent the final product. Often, the design starts as a simple hand-drawn sketch, which is then transformed into a precise digital model.

2. Convert CAD to CAM

While CAD provides a visual representation of the part, CNC machines require instructions in a format they can understand. This is where Computer-Aided Manufacturing (CAM) software comes into play. CAM software converts the CAD model into a format that provides specific manufacturing instructions for the CNC machine.

The conversion process involves generating G and M codes. G codes control the cutting tool’s coordinates, while M codes manage auxiliary functions like coolant flow.

3. Machine Setup

Once the design is ready in CAM format, the next step is to set up the machine. This involves calibrating the machine tools and mounting the workpiece securely. Different precision machining tools are used based on the material and design requirements. It’s crucial to ensure all clamps are tightened correctly and that machine parameters, such as coolant levels, are properly set.

4. Execute the Machining

With the machine set up, the program is ready to run. Most CNC machines have a display to monitor the process and make adjustments if needed. When the program is executed, the machine begins the precision machining process, carefully following the instructions to produce the part.

5. Completion

Once the machining process is complete, the part is removed from the machine. Depending on the project requirements, the part may undergo secondary processes such as grinding or polishing. However, many precision-machined parts are ready for use immediately without any additional processing.

Conclusion

Precision machining is the backbone of modern manufacturing, enabling the production of parts with unmatched accuracy and efficiency. By combining high-quality tools, advanced CNC machines, and a well-structured process, precision machining ensures that the intricate components we rely on every day are produced to the highest standards. Whether for automotive, aerospace, medical devices, or any other industry, precision machining plays a critical role in making the world’s most advanced technologies possible.

For all your precision Machining needs contact Atscott MFG. Located in Pine City, MN