Transforming Parts and Materials to Market-Ready Products

We offer a complete variety of metal fabrication services, including CNC laser and waterjet cutting, punching, shearing, welding, and more. Our expert metal fabrication services combined with a full range of in-house machining, turning, media blasting, cleaning/degreasing, powder coating, and assembly, make Atscott Mfg. an efficient, affordable, and capable choice for your complex projects.

Our complete line of sheet metal fabrication equipment includes shears, press brakes, punch presses, welding equipment, and more.

Process Versatility Brings Better Solutions

We integrate our expertise in sheet metal fabrication with a full range of machining, turning, metal finishing, and assembly services. With this wide range of capabilities, Atscott offers customers a start-to-finish option on their products, eliminating the need for additional vendors, reducing lead times, and increasing overall product quality.

Metal Fabrication Services

We offer the following metal fabrication services:

- CNC Laser cutting

- CNC waterjet cutting

- CNC Punching

- Welding, MIG and TIG

- Shearing

- CNC forming

- Permanent fastener insertion

Materials

At Atscott, we work with a variety of materials, including:

- Most grades and gauges of steel sheet

- Aluminum sheet

- Stainless steel sheet

- Other metal sheet

- Composites

- Specialty materials

Powder-Coat Finishing

At Atscott, we offer our customers a true one-stop-shop sourcing option with a full finishing line in-house. Media blasting, a 5-stage wash, and powder-coating equipment are set up as a line within our facilities.

Much more environmentally-friendly than liquid paint application, powder-coating provides a strong, durable, and uniform finish for many sheet metal parts and assemblies processed by Atscott Mfg, Inc. on a regular basis.

In addition to standard single-coat applications, we also offer 2-coat powder coating options incorporating use of metal-specific corrosion resistant primers applied below the surface color of your choosing. Indoor and outdoor rating coating options are also available!

Parts Photo Gallery

Click a photo below to view some of our quality fabricated metal parts.

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

- 1150 Holstein Drive NE., Pine City, MN 55063 PHONE: 320-629-2501 FAX: 320-629-7129 EMAIL: info@atscott.com

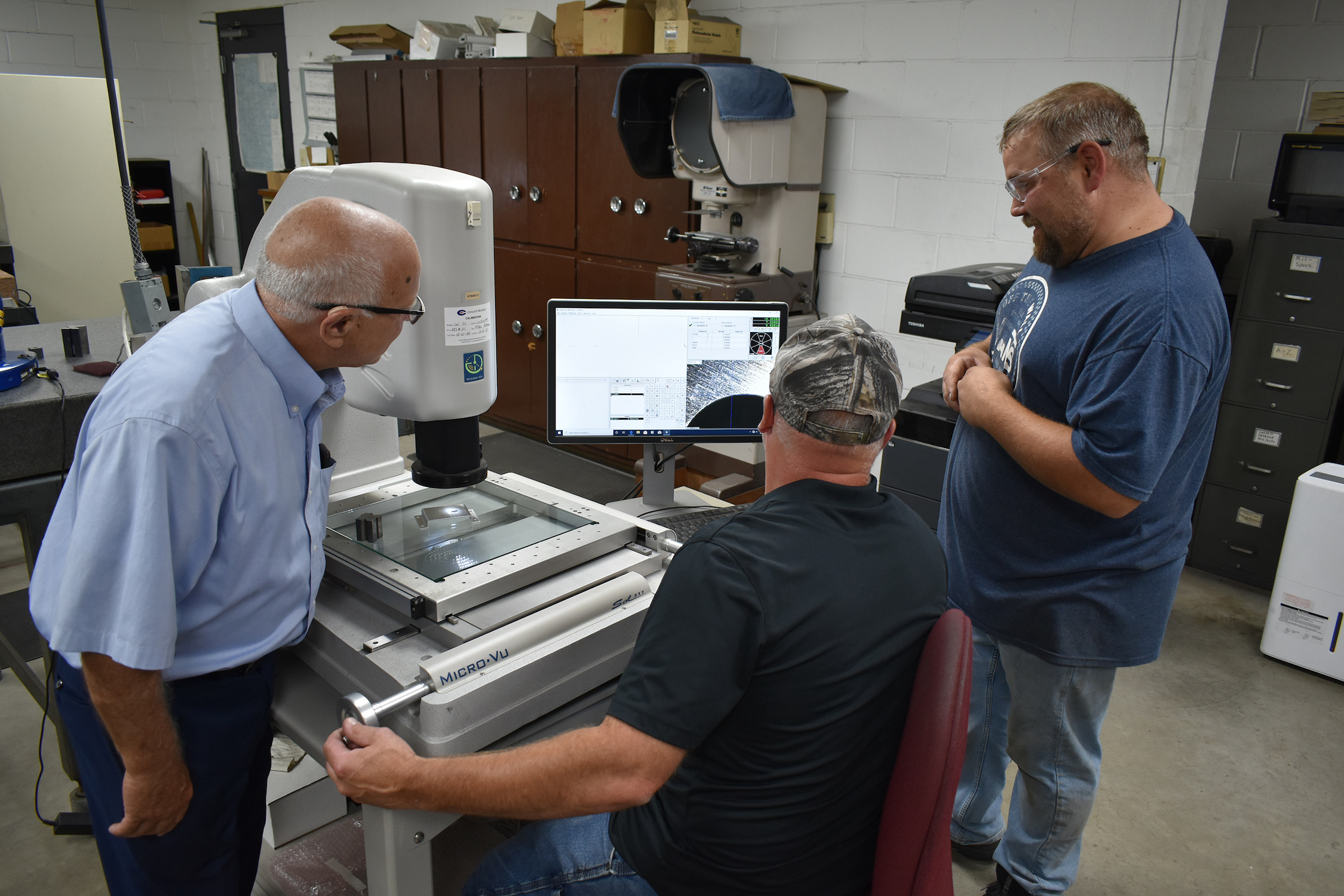

The Atscott Mfg. Quality Commitment

As a contract manufacturer specializing in metal fabrication, machining, painting, and assembling all forms of manufactured parts and assemblies, we are committed to meeting your requirements on each and every order involving any of these processes. We are proud to employ a staff of experienced and dedicated full-time inspectors, responsible for review and approval of every piece, part, and project completed by Atscott’s production teams.

We are proud to have earned the following quality certifications.

Our team members refresh their skills annually through systematic training with Pine Technical College System and Enterprise Minnesota. As a product of continual investment in its employees and application of this further education, Atscott has been bestowed numerous customer awards and recognitions for quality, service, delivery, and cost control.