Choosing the Right Metal Fabrication Company: A Complete Guide

October 31, 2025Choosing the right sheet metal fabrication partner can make or break your project—whether you’re working in construction, manufacturing, industrial production, or commercial applications. Not every fabricator is equipped to handle every type of job, and choosing the wrong partner can lead to costly delays, design issues, and inconsistent quality.

If you’re searching for a reliable partner in Minnesota, Atscott Manufacturing in Pine City, proudly serving the entire Twin Cities area, is a trusted option.

1. Experience Matters

Experience is one of the most important factors when selecting a fabrication partner. A company with a proven track record in your industry will understand your unique needs, challenges, and project expectations.

Atscott Manufacturing, serving all of Minnesota for over 60 years, brings decades of expertise across a wide range of industrial and commercial applications.

Key Questions to Ask

- Have they completed projects similar to yours?

- Do they have clients in your industry?

- Can they manage the scale and complexity of your project?

- How experienced are their team members and leadership?

2. Evaluate Their Equipment and Technology

A reliable sheet metal fabrication partner should use modern technology and well-maintained equipment. Updated tools, automation systems, and precision machinery reduce errors, improve consistency, and speed up production timelines.

If your project requires specialized capabilities, make sure your fabricator has the equipment—or is willing to invest in it.

Key Questions to Ask

- What technologies and fabrication methods do they currently use?

- Are they open to adopting new equipment for specialized projects?

- Who is responsible for covering the cost of additional tooling or machinery?

3. Prioritize Availability and Communication

In today’s world, supply chain fluctuations and scheduling changes are common. Your fabrication partner should be flexible enough to adapt when needed, helping you stay on schedule even when unexpected issues arise.

Clear, consistent communication is equally important. A strong fabrication partnership requires transparency, responsiveness, and proactive problem-solving.

Key Questions to Ask

- How flexible are they when project needs or timelines shift?

- Do they provide consistent communication at every stage of the process?

- Are they proactive about identifying potential issues early?

4. Assess Their Capabilities

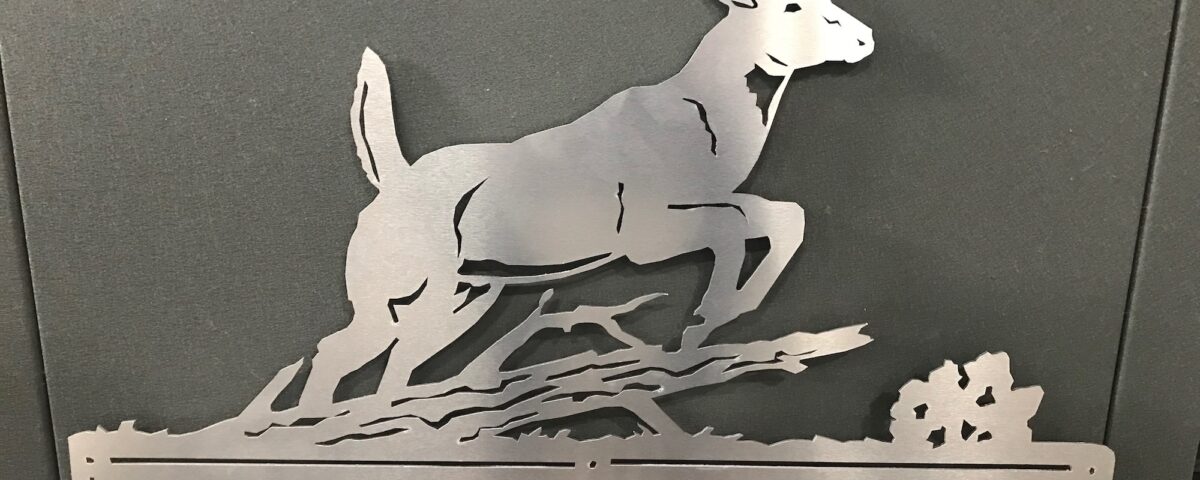

Not all fabricators offer the same level of service. Some handle only basic work, while others provide full-service fabrication—from design and prototyping to production, finishing, and assembly.

Choose a partner with the full range of capabilities required to bring your project from concept to completion.

Why Choose Atscott Manufacturing?

Using these guidelines will help you make an informed decision when selecting a sheet metal fabrication partner.

Atscott Manufacturing checks all the boxes with:

- More than 60 years of industry experience

- Advanced equipment and fabrication technology

- Flexible production capabilities

- Clear, reliable communication

- A broad ability to support simple parts or complex custom fabrication projects

Located in Pine City, Minnesota and serving the entire Twin Cities area, Atscott is prepared to help bring your project to life with precision, reliability, and exceptional service.

Ready to Get Started?

Contact Atscott Manufacturing today to discuss your project and discover how the right fabrication partner can make all the difference.